It took over a month to solve

The claims follow the fourth anniversary of Russia's invasion of Ukraine

Police concluded a four-month investigation before an arrest warrant was issued

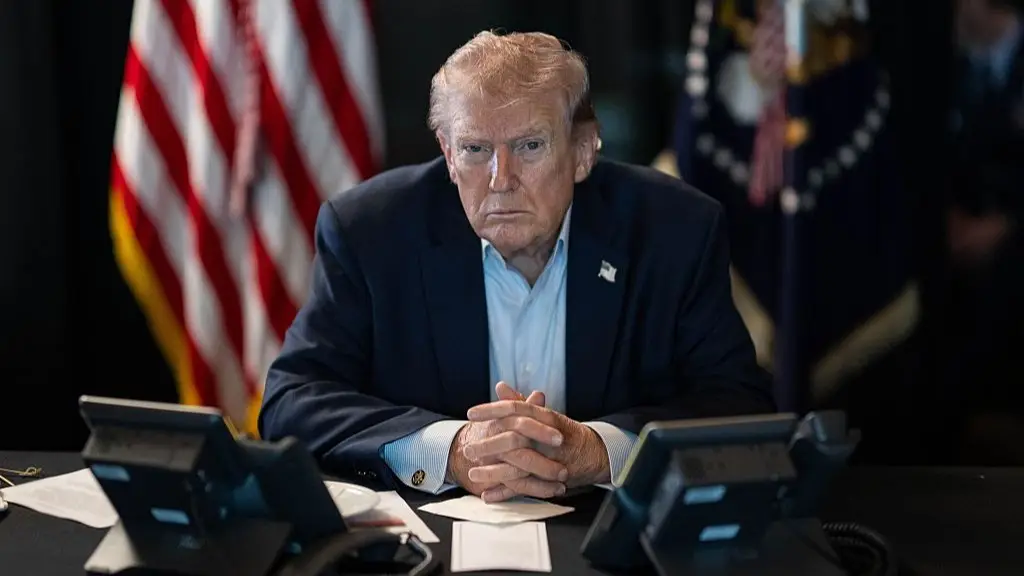

He has called for 'unconditional surrender' from Iran

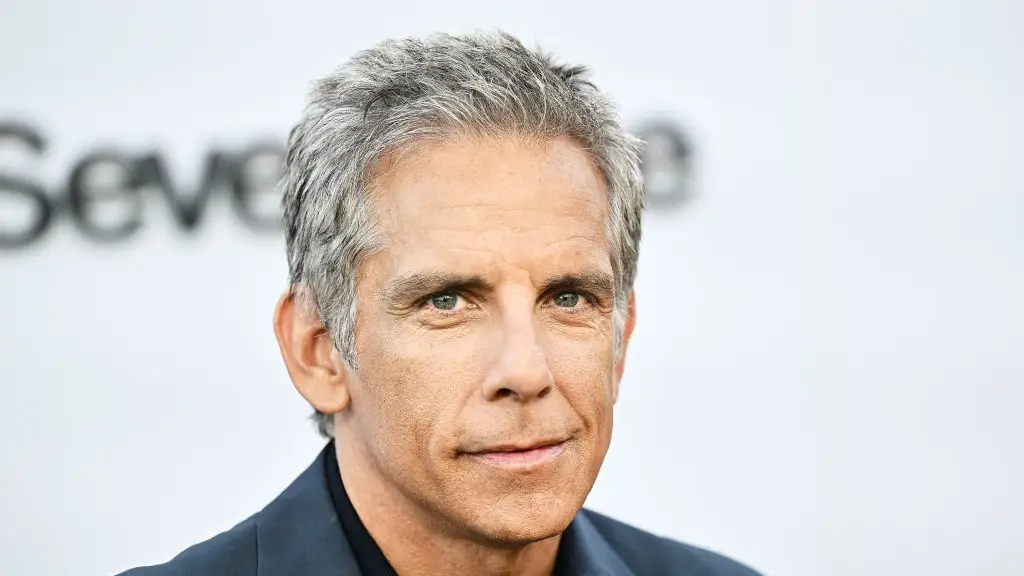

The American actor described it as 'propaganda'

The war in Iran has now been going on for a week

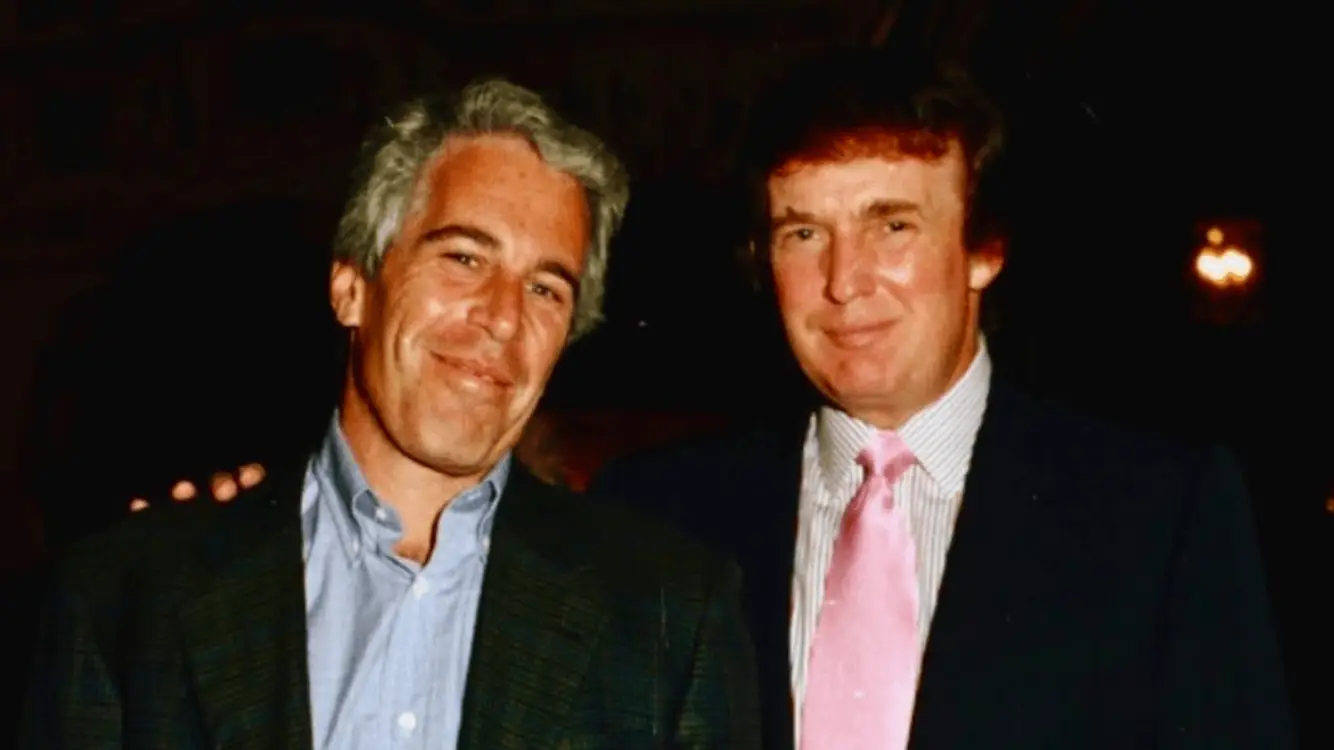

The US and Israel's actions against Iran have sparked concerns about a third world war

His attacker is said to have shouted 'I've done it' after the attack

breaking

The UK government has slammed the controversial moment

Charles 'Sonny' Burton, 75, has spent more than three decades on Alabama’s death row

President Donald Trump has appeared to rule out talks with Iran unless one condition is met

Seven other countries will also boycott the ceremony

It comes more than five years after the initial incident

NASA has provided an update on near-Earth asteroid 2024 YR4

It isn't as bad as many might think

Applegate says she was 'disgusted by what came out of my mouth'

New York Democratic Rep. Alexandria Ocasio-Cortez has slammed President Trump

An investigation by Poland-based news outlet Vot Tak has found that Russia is fast-tracking war veterans from hospital wards

There are a lot of people all trying to leave on the same flights

Russian and Belarusian flags will be flown across Lombardy and Northeast Italy

Yvonne Ford, from Barnsley in Yorkshire, died after contracting the fatal virus on holiday in Morocco

Molly Lambert used to question if her loved ones were 'safe' around her